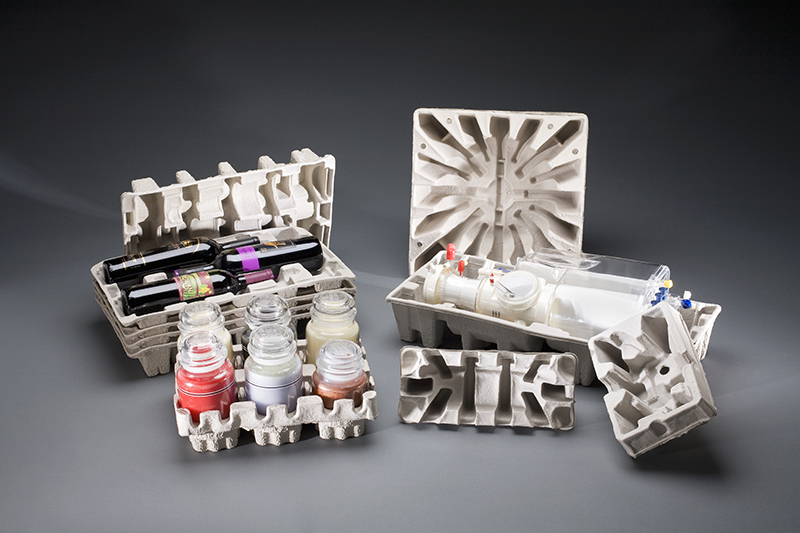

Sustainable, Environmentally Responsible Protective Packaging

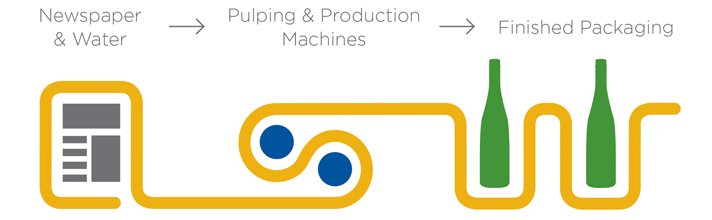

Made from 100% post-industrial recyclable materials, molded fiber/molded pulp is a cost effective and environmentally friendly packaging solution that reduces packing labor and require less storage space while providing superior protection at every stage of the supply chain.

Made from 100% post-industrial recyclable materials, molded fiber/molded pulp is a cost effective and environmentally friendly packaging solution that reduces packing labor and require less storage space while providing superior protection at every stage of the supply chain.

The inherent flexibility of molded fiber offers substantial cushioning qualities and the "geometry" that we incorporate into each design lends strength to each part.

For over 30 years, MFT-CKF has delivered innovative and environmentally-responsible, protective packaging solutions to the consumer goods, electronics, and industrial products sectors across North America.

Features and Benefits

|

Features

|

Benefits

|

|---|---|

| Molded fiber is cost competitive | Helps reduce packaging costs |

| Material is strong, yet flexible | Provides excellent product protection |

| Molded fiber packaging nests and stacks easily | Efficient use of shipping and storage space |

| Molded fiber comes ready to use with no assembly needed | Reduces labor required for packaging end products |

| Made from recycled material and is recyclable | An environmentally responsible protective |

| Tools are precision machined from aluminum or plastic | Tools last longer |

| MFT-CKF is vertically integrated | Good designs improve performance and cuts costs |

| Most capacity in the industry | Economies of scale can help reduce overall costs |

Packaging Material Comparison

|

Feature

|

Molded Fiber

|

Corrugated Fiberboard

|

Thermoformed Plastic

|

Expanded Polystyrene (EPS)

|

|---|---|---|---|---|

| Cost | Medium | Low | Medium | Medium |

| Shipping & storage efficiency | Nests well | Stores flat | Nests well | No nesting |

| Project development time | 4-6 weeks | 2-3 weeks | 4-6 weeks | 4-6 weeks |

| Assembly & handling | No assembly required | Assembly required | No assembly required | No assembly required |

| Environmental | Recycled and recyclable | Some recycled content | Some recycled content | Claims to be but not practical |

Sustainable, Environmentally Responsible Protective Packaging

Sustainable, Environmentally Responsible Protective Packaging